In a world once shadowed by supply chain snarls and production stalls, the global manufacturing landscape is witnessing a renaissance. After more than two years of contraction, factories are humming again, bringing hope to executives, workers, and communities that depend on vibrant industrial activity. Across continents, this revival is not a coincidence but the fruit of calculated improvements within the logistical web that underpins modern production.

The latest data reveals that manufacturing PMI rose to 50.9 in the United States for January 2025, marking the end of a prolonged downturn. This turning point drove a surge in factory employment, as companies filled positions to meet growing demand in industrial machinery and electronics. Meanwhile, France saw a 1.4% jump in manufacturing output in February, erasing January’s losses and emphasizing how nimble supply chains can spark immediate gains.

These successes speak to a broader narrative of resilience and agility. Manufacturers are not only rebuilding inventories but also rethinking their strategies—embracing technological innovation, fostering stronger partnerships with logistics providers, and championing sustainable practices. As we delve into the factors fueling this resurgence, one theme stands clear: logistics is the lifeblood of manufacturing, and its optimization can unlock unparalleled growth.

The U.S. manufacturing sector’s return to growth was no accident. After two years under contractionary pressures, the Institute for Supply Management reported a PMI reading above the 50 threshold, signaling renewed expansion. Increased new orders, particularly in heavy equipment, aerospace components, and consumer electronics, have propelled output forward, while businesses remain cautious in their staffing, hiring gradually to avoid overextension.

Across the Atlantic, Europe’s story mirrors this optimism. France’s upward revision of January data and the subsequent 0.7% increase in overall industrial production underscore how improved data accuracy can reshape strategic decisions. In Germany and Italy, automobile and machinery manufacturers are leveraging enhanced forecasting tools to align production with real-time market signals—illustrating how data transparency and logistical coherence are woven into the fabric of modern manufacturing.

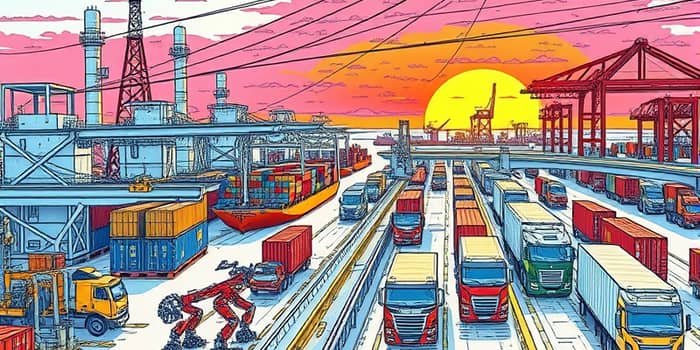

At the heart of this manufacturing renaissance lies easing shipping bottlenecks and delays. Ports are expanding night-shift operations, rail connections are receiving infrastructure upgrades, and digital customs platforms are accelerating clearance times. These enhancements collectively shrink lead times and free up capital that was once trapped in excess inventory.

Meanwhile, companies are investing in advanced warehouse management systems equipped with AI-driven routing algorithms. By optimizing storage layouts and automating order fulfillment, firms can achieve same-day dispatch rates and significantly cut overhead costs. This level of precision ensures that materials and components flow seamlessly from suppliers to production lines, sustaining momentum throughout the entire value chain.

Leading manufacturers are demonstrating an exceptional ability to quickly ramp production by integrating advanced digital solutions and agile methodologies. Tesla’s Gigafactory in Shanghai stands as a prime example: after scheduled downtime, it pivoted back to full capacity in record time, contributing over 222,000 vehicles in one quarter—more than half of the company’s global deliveries.

These successes are underpinned by a suite of cutting-edge technologies:

By embracing Industry 4.0 principles, manufacturers can detect potential issues before they escalate, adjust workflows on the fly, and maintain quality at scale. This adaptability is especially crucial amid policy fluctuations and volatile commodity markets.

Not all industries have rebounded at the same pace. While defense, automotive, and technology sectors are registering robust order growth, consumer goods and textiles are navigating a slower recovery. Understanding these divergences allows companies to allocate resources effectively and identify new opportunities.

Despite clear gains, manufacturers face headwinds that require proactive management. Tariff uncertainties, rising energy prices, and labor market tightness can quickly erode profit margins. Additionally, late Q2 declines in port throughput signal that businesses are still wary after aggressive inventory buildups earlier in the year.

To build resilience amid global uncertainties, companies can adopt several strategic measures:

By embedding these practices, organizations not only weather storms but also position themselves to capitalize on new market openings as they arise. Collaboration with government agencies and industry consortia can further strengthen supply chain visibility and promote standardization across borders.

Industry forecasts for 2025 and beyond remain upbeat, projecting accelerated growth if logistical momentum endures. The Asia-Pacific region, spearheaded by chipmaking hubs in Taiwan and South Korea, is poised to drive global output forward. Yet sustainability concerns are becoming equally central, with manufacturers exploring renewable energy integration and circular economy principles to reduce environmental footprints.

This era of manufacturing resurgence is not just about output figures; it is a testament to human ingenuity, collaboration, and determination. As factories around the world adapt to a complex tapestry of challenges, they also demonstrate that through innovation and strategic logistics, any obstacle can become an opportunity.

For business leaders, policy makers, and workers alike, the message is clear: invest in efficient logistics, harness technology, and cultivate agility. These pillars will define the next wave of industrial progress, ensuring that manufacturing remains a vibrant engine of growth and prosperity in an ever-changing global landscape.

Crucially, fostering a skilled workforce is integral to sustaining this upward trajectory. Companies are partnering with universities and vocational institutes to develop targeted training programs that blend digital literacy with hands-on technical expertise. By equipping employees with the skills to operate advanced machinery, analyze supply chain data, and lead continuous improvement initiatives, manufacturers can safeguard their competitive edge in a rapidly evolving marketplace.

Moreover, public and private stakeholders must work in concert to upgrade infrastructure, harmonize trade regulations, and incentivize sustainable practices. When communities, governments, and businesses unite around a shared vision of resilient, efficient manufacturing ecosystems, the result is not only economic growth but also environmental stewardship and social well-being. This holistic approach will chart the course for a resilient industrial future where technological progress and human prosperity go hand in hand.

References